AI-Driven Process Automation: Requires A Disciplined Path to Deliver Productivity, Quality and Compliance Objectives

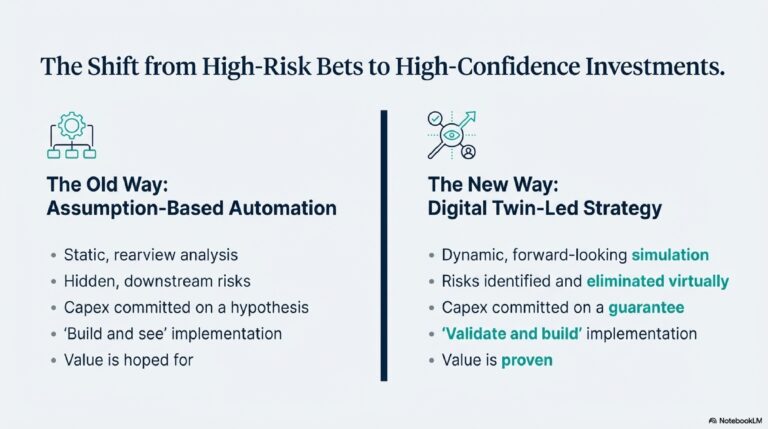

The risk of speed without discipline introduces risk to enterprises who are increasingly seeking to adopt AI to accelerate process automation. The promise is compelling: higher productivity, lower cost, and workforce optimization.

The reality, however, is that speed without discipline can degrade process understanding, erode the workforce’s institutional knowledge, and create costly integration gaps when new AI capabilities are layered onto flawed designs.

To win in today’s expanding threat landscape and increasingly regulated environments, manufacturers and energy companies must pair AI with proven process re-engineering techniques that have proven themselves across industries for decades.

A Proven Framework for AI-enabled Process Automation

1️⃣ Value stream mapping for process re-engineering

Start with a holistic view: map a process from start to finish, scrutinizing every step for waste, variance, and risk. Apply Lean and Six Sigma to identify opportunities for improvement before automation.

2️⃣ Information Quality

Integrate Information Quality assessment to improve system trust in the results generated. This “quality by design” mindset prevents automation from utilizing untrusted information that can amplify defects and result in bad outcomes.

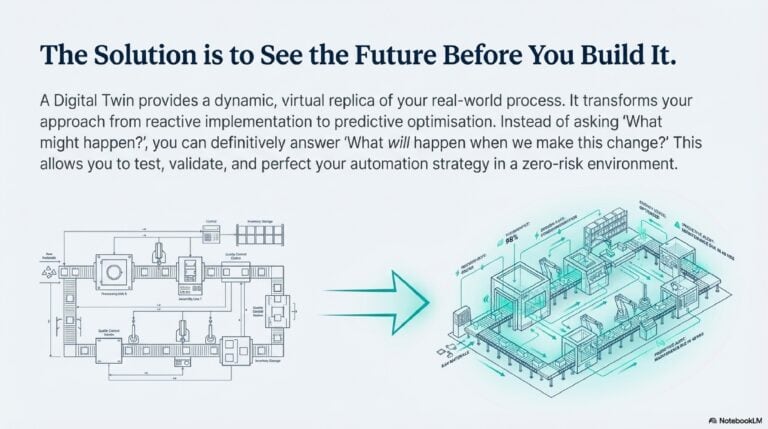

3️⃣ Digital Twin and “what-if” testing

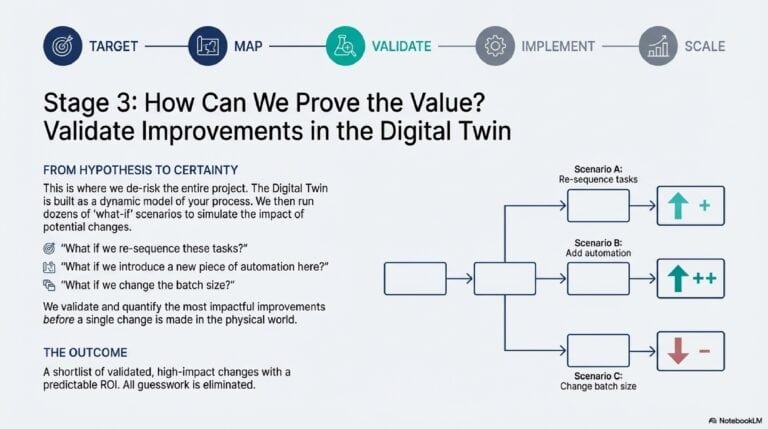

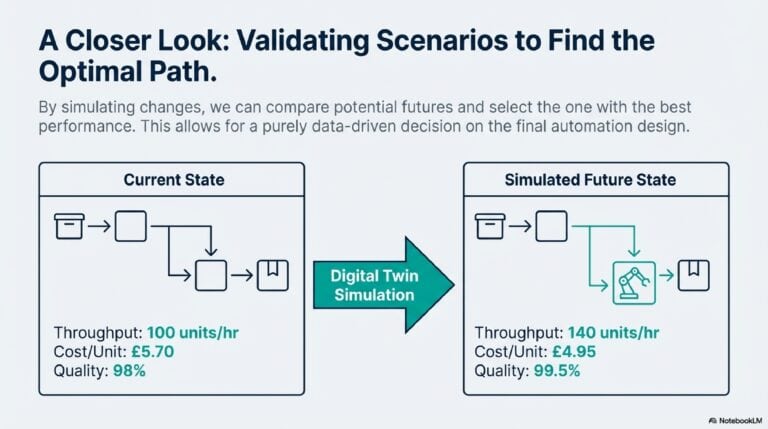

Build a Digital Twin of the target process to simulate throughput, cost, quality, and service impact under multiple scenarios. Validate improvements in a risk-adjusted environment before the release into a production deployment.

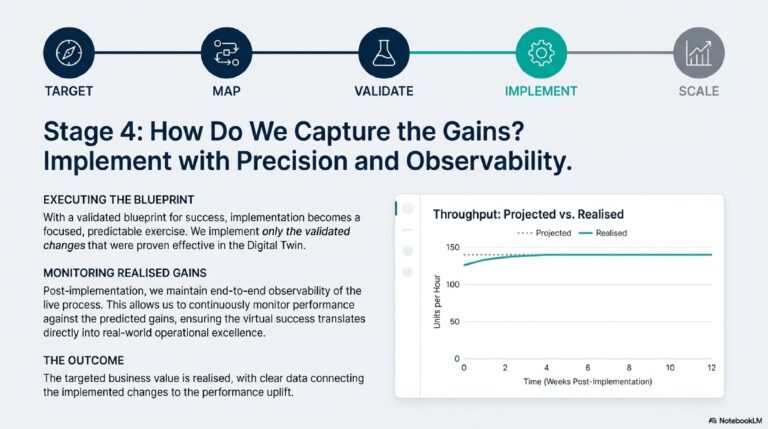

4️⃣ Observability and Building a Community of Learning

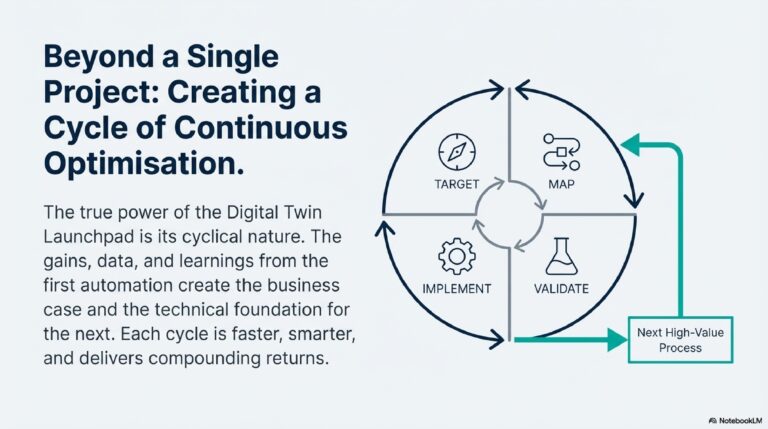

End-to-end observability ensures governance, rapid issue resolution, and auditable evidence of continuous improvement. A library of validated process patterns accelerates future engagements and compounds value.

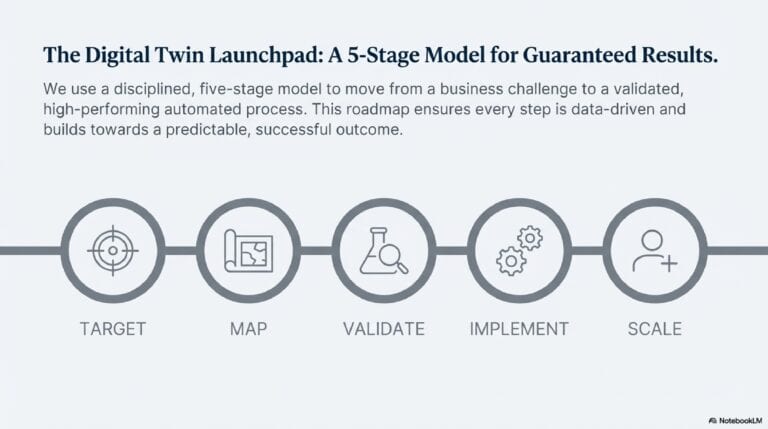

Triplett Services and Processbots.ai utilize a Five-stage delivery model

Triplett Services and Processbots.ai utilize a Five-stage delivery model

Why this matters for regulated and discipline process automation: e.g., manufacturing and energy sectors?

- Lean/Six Sigma discipline remains the backbone of reliable process design. AI augments, rather than replaces, the engineering rigor that yields safe, compliant, and high-quality outcomes.

- End-to-end governance and observability are non-negotiable in regulated environments. They provide auditable evidence of ROI and risk reduction, which is essential for capital approvals and ongoing investments.

- Reusable libraries provide for a community of learning and accelerate process maturity, helping organizations scale improvements across plants, lines, and assets.

Where and How to Begin?

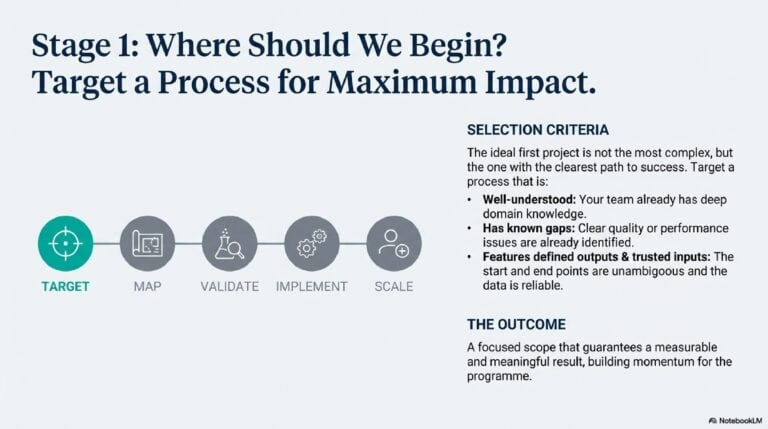

- Target a well-understood process with known quality or performance gaps, clearly defined outputs, and trusted inputs.

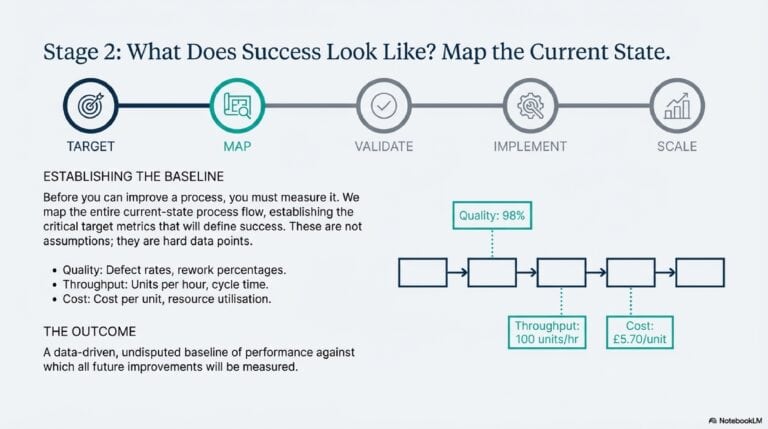

- Map the current-state process, establishing target metrics for quality, throughput, and cost.

- Build the Digital Twin to run what-if scenarios, validating the most impactful improvements before automation.

- Implement only validated changes, following the five-stage model, and maintain end-to-end observability to monitor realized gains.

- Decide on the level of in-house capability you wish to build, with the expectation that internal design capability often begins after the second automation.

- Map the current-state process, establishing target metrics for quality, throughput, and cost.

Where and How to Begin?

- Target a well-understood process with known quality or performance gaps, clearly defined outputs, and trusted inputs.

- Map the current-state process, establishing target metrics for quality, throughput, and cost.

- Build the Digital Twin to run what-if scenarios, validating the most impactful improvements before automation.

- Implement only validated changes, following the five-stage model, and maintain end-to-end observability to monitor realized gains.

- Decide on the level of in-house capability you wish to build, with the expectation that internal design capability often begins after the second automation.

- Map the current-state process, establishing target metrics for quality, throughput, and cost.

Frequently Asked Questions (FAQs)

What is the right starting point for AI-enabled process automation?

Begin with a clearly defined process, a trusted data set, and measurable outcomes. Validate through a Digital Twin before automating.

How does this approach manage risk and regulatory compliance?

By embedding applicable regulatory guidance, enterprise policies & standard operating procedures, coupled with Information Quality from the beginning of the design phase, and by maintaining and providing end-to-end observability for governance and auditability.

Can this approach scale across multiple plants or sites?

Yes! The five-stage model, combined with learning libraries, and benchmarking analysis, it supports repeatable deployments and rapid scaling and best practice sharing while preserving quality and safety standards.

How does Triplett Services enhance the process?

Triplett Services brings deep governance, risk management, and organizational change management deep experience, complemented by a trusted partnership with Processbots.ai to deliver end-to-end AI-enabled automation with rigorous design discipline.

Conclusion

Enterprises seeking durable productivity gains, cost reduction, and risk-managed AI adoption should pursue disciplined AI-enabled process re-engineering. Triplett Services, in partnership with Processbots.ai, offers a proven path that starts with a rigorous process design, validated improvements via Digital Twin, and a staged, auditable deployment that builds internal capability over time.

Contact Triplett Services or Processbots.ai to discuss a tailored assessment and a practical roadmap for AI-enabled process automation that protects knowledge, elevates quality, and drives measurable ROI.

Related Posts

Workflow Automation Governance: How Enterprises Scale Automation Without Losing Control

Why Workflow Automation Governance Matters Now? Workflow automation is rapidly becoming a core enterprise capability.…

Before You Automate Anything: Why Process Optimization Must Come First

In today’s environment of rapid digital transformation, many organizations feel pressure to “automate everything.” Software…

Leave a Reply